Saturday, December 29, 2007

Aloft at Last

METAR KBMI 292056Z 22006KT 10SM OVC016 M01/M04 A3007 RMK AO2 56013 T10111038 SLP203

Translation: Wind: blowing from 220° at 6 knots; Visibility: 10 statue miles; Sky condition: overcast at 1,600 feet above ground level; Temperature: -1°C; Dewpoint: -4°C

Not the best conditions, and they were barely VFR, but it was worth a try just to get in the air again for our first flight after five months in the shop due to a cracked crankcase.

After a bit of confusion during runup (I mistook the new mixture control for the prop control) I actually remembered how to takeoff and we were finally airborne. Break-in instructions call for running the engine at generally high power setting (above 65%) so as to seat the piston rings. I ran her at 23 inches of manifold pressure and 2,500 RPM, which under standard conditions would be roughly 75%. Cold temperatures typically mean higher performance for a given power setting, and although I don't know eaxctly how much that impacted the horsepower percentage, it was definitely reflected in the airspeed. In level flight, I was operating in the caution range (the yellow arc on the airspeed indicator, from 155 - 185 MPH) for much of the flight.

After a bit of confusion during runup (I mistook the new mixture control for the prop control) I actually remembered how to takeoff and we were finally airborne. Break-in instructions call for running the engine at generally high power setting (above 65%) so as to seat the piston rings. I ran her at 23 inches of manifold pressure and 2,500 RPM, which under standard conditions would be roughly 75%. Cold temperatures typically mean higher performance for a given power setting, and although I don't know eaxctly how much that impacted the horsepower percentage, it was definitely reflected in the airspeed. In level flight, I was operating in the caution range (the yellow arc on the airspeed indicator, from 155 - 185 MPH) for much of the flight.

It was pretty murky below the overcast, but as we continued around the area, the skies began to clear a bit and I found holes large enough to allow a peek above the cloud layer. I wouldn't wasn't to have to descend through those clouds - the layer wasn't that thick, but at a few degrees below freezing, ice would be a problem. I kept a careful eye on the hole.

It was pretty murky below the overcast, but as we continued around the area, the skies began to clear a bit and I found holes large enough to allow a peek above the cloud layer. I wouldn't wasn't to have to descend through those clouds - the layer wasn't that thick, but at a few degrees below freezing, ice would be a problem. I kept a careful eye on the hole.

The engine monitor in action. Cylinder #3 is running a bit leaner than the other cylinders, but that is supposedly normal for this engine. What is curious is that the cylinder head temperature for #3, which typically runs hotter than the others, is significantly cooler. This may be due to the fact that #3 has a different type of temperature probe which allows the EDM-700 and the factory cylinder head temperature gauge to read from the same socket on the cylinder head. The numeric readout "23 IAT" is the carburetor inlet temperature. The manual indicates that this should read "CRB" instead of "IAT" (which stands for Induction Air Temperature, a measure of the temperature of air entering the intercooler of a supercharged engine) We had issues with the connectors of the wiring harness during installation of the EDM-700, so this may be another mismatched connector.

The engine monitor in action. Cylinder #3 is running a bit leaner than the other cylinders, but that is supposedly normal for this engine. What is curious is that the cylinder head temperature for #3, which typically runs hotter than the others, is significantly cooler. This may be due to the fact that #3 has a different type of temperature probe which allows the EDM-700 and the factory cylinder head temperature gauge to read from the same socket on the cylinder head. The numeric readout "23 IAT" is the carburetor inlet temperature. The manual indicates that this should read "CRB" instead of "IAT" (which stands for Induction Air Temperature, a measure of the temperature of air entering the intercooler of a supercharged engine) We had issues with the connectors of the wiring harness during installation of the EDM-700, so this may be another mismatched connector.

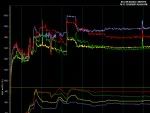

Here's the graph of the flight downloaded from the EDM-700 and displayed in JPI's EzTrends program. The top lines show the exhaust gas temperatures plotted against the y-axis scale on the left of the chart. The bottom lines show cylinder head temperatures plotted against the y-axis scale on the right. Flight events such as engine start and warm-up, takeoff and climb, level-off, landing, and the long taxi back to the ramp are evident. The major spikes in the EGT graph correspond to mixture adjustments I made while exploring the EDM-700's lean-find function, and a few in-flight magneto checks.

Here's the graph of the flight downloaded from the EDM-700 and displayed in JPI's EzTrends program. The top lines show the exhaust gas temperatures plotted against the y-axis scale on the left of the chart. The bottom lines show cylinder head temperatures plotted against the y-axis scale on the right. Flight events such as engine start and warm-up, takeoff and climb, level-off, landing, and the long taxi back to the ramp are evident. The major spikes in the EGT graph correspond to mixture adjustments I made while exploring the EDM-700's lean-find function, and a few in-flight magneto checks.

After 2.3 hours in the air, it was time to come home again. I still remember how to land a Cardinal. It was basically a trouble free flight, and the only squawk (apart from the IAT/CRB readout) was an oil leak which was easily diagnosed and fixed.

After 2.3 hours in the air, it was time to come home again. I still remember how to land a Cardinal. It was basically a trouble free flight, and the only squawk (apart from the IAT/CRB readout) was an oil leak which was easily diagnosed and fixed.

Here's where we went, according to the GPS track downloaded and shown in Google Earth.

Here's where we went, according to the GPS track downloaded and shown in Google Earth.

Wow! My highest "annual" was $8,600 and only included a cylinder rebuild, and prop and governor overhaul. Of course, the little things add up. A fresh engine and all the other new parts for $16k seems like a good value.

I read your posts and my mouth watered. The thought of having been able to put a freshly rebuilt engine, newly painted parts and hoses, and especially a repaired and painted cowling on my Skylane at some point is exciting. A clean, painted, and shiny engine compartment would have been heaven!

I know the pain of the checkbook when making repairs to your bird, but we quickly forget that pain when we walk up to it knowing the difference. Sorry you had the downtime, but congratulations on the fresh beginning.

Good call on the engine monitor and preheat system. Once you have them you never know how you lived without them. Anything I buy in the future will have the engine monitor for sure.

Enjoy! and Fly safe.

Shawn

Aircraft Ownership Blog

I want to let you know how much I enjoy your postings, to me its like a new TV show episode each time :)-please keep them coming!

Pablo

Delray Beach, FL